AFL VTC Vertical Tube Coalescing Separator

VTC Vertical Tube Coalescing Separator

The VTC Vertical Tube Coalescing Separator is a rectangular above, below and flush-with-grade vertical tube coalescing separator and is used when a large internal oil storage chamber is required. A rotary pipe skimmer is used to constantly or periodically draw off separated oil for removal. Flow rates from 5-2200 gpm in a single unit.

The VTC SERIES removes

- free oils and mechanically emulsified oils

- settleable solids

from industrial wastewater and coolant.

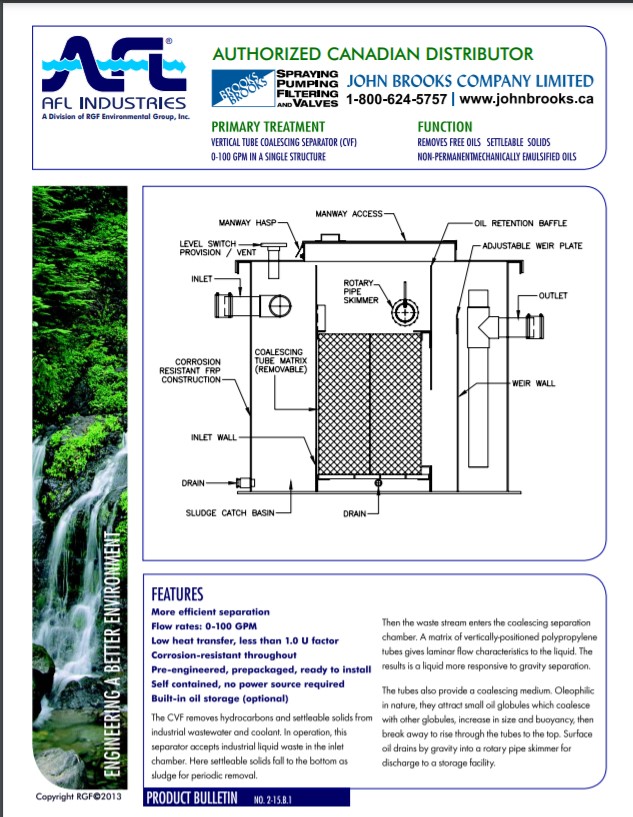

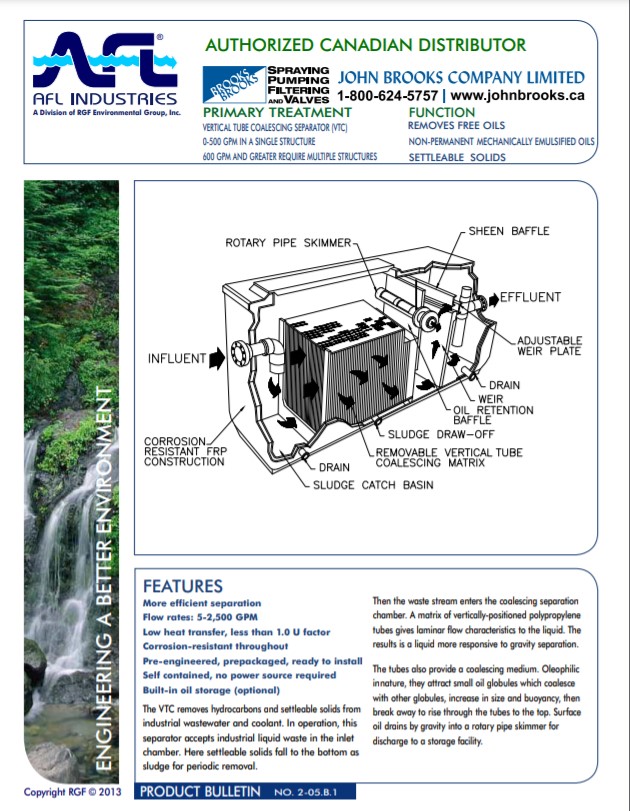

The VTC removes hydrocarbons and settleable solids from industrial wastewater and coolant. In operation, this separator accepts industrial liquid waste in the inlet chamber. Here settleable solids fall to the bottom as sludge for periodic removal. Then the waste stream enters the coalescing separation chamber. A matrix of vertically-positioned polypropylene tubes gives laminar flow characteristics to the liquid. The result is a liquid more responsive to gravity separation. The tubes also provide a coalescing medium. Oleophilic in nature, they attract small oil globules which coalesce with other globules, increase in size and buoyancy, then break away to rise through the tubes to the top. Surface oil drains by gravity into a rotary pipe skimmer for discharge to a storage facility.

Performance Expectations of the VTC Vertical Tube Coalescing Separator

1. Removal of oil globules down to 20-micron size

2. Reduction of oil content to 10mg/ltr/10ppm

The VTC removes even non-permanent mechanically emulsified oil. It leaves no visible sheen and traps solids too. In metalworking and similar applications, it removes more than 99% of tramp oils from coolants.

The VTC incorporates a molded fiberglass or stainless steel construction. Internally reinforced, the structure withstands severe soil and hydraulic loadings. The entire exterior surface is covered with corrosion-resistant gel-coat, integrally-colored and ultraviolet resistant. Since the envelope and fittings are corrosion-resistant, the separator can be installed in many hostile environments. No sacrificial protection required.

Benefits of the VTC Vertical Tube Coalescing Separator

- More efficient separation

- Flow rates: 5-2,200 GPM (18-8,325 L/min)

- Low heat transfer, less than 1.0 U factor

- Corrosion- resistant FRP construction

- Pre-engineered, prepackaged, ready to install

- Self-contained, no power source required

- Built-in oil storage (optional)

- Inlet diffuser promoting laminar flow

VTC Vertical Tube Coelescing Separator – Applications

- Airports and aircraft services

- Transportation and equipment wash pads

- Electric utilities and power plants

- Environmental remediation

- Military and government facilities

- Petroleum marketing facilities

- Railroad yards

- Petroleum and other fueling facilities

- Oil storage areas

- Treatment of industrial process wastewater

- Bilge water accumulated in ships

Model # |

Flow

|

Total

|

Operational

|

Installation |

|---|---|---|---|---|

| VTC-5-SS | 5 GPM | 34 | 380 | Above |

| VTC-10-SS | 10 GPM | 91 | 918 | Above |

| VTC-20 | 20 GPM | 290 | 2,900 | Above/Below/Flush |

| VTC-50-SS | 50 GPM | 797 | 7,750 | Above/Below/Flush |

| VTC-50 | 50 GPM | 725 | 6,500 | Above/Below/Flush |

| VTC-100 | 100 GPM | Call for Details | Call for Details | Above/Below/Flush |

| VTC-200 | 200 GPM | 1420 | 13,500 | Above/Below/Flush |

| VTC-300 | 300 GPM | 2130 | 19,800 | Above/Below/Flush |

| VTC-400 | 400 GPM | 2840 | 26,150 | Above/Below/Flush |

| VTC-500 | 500 GPM | 3560 | 34,600 | Above/Below/Flush |

| VTC-600 | 600 GPM | Call for Details | 39,600 | Above/Below/Flush |

| VTC-800 | 800 GPM | Call for Details | 52,000 | Above/Below/Flush |

| VTC-1000 | 1000 GPM | Call for Details | 69,200 | Above/Below/Flush |

| VTC-1200 | 1200 GPM | Call for Details | 79,200 | Above/Below/Flush |

| VTC-1600 | 1600 GPM | Call for Details | 104,000 | Above/Below/Flush |

| VTC-2000 | 2000 GPM | Call for Details | 138,400 | Above/Below/Flush |

| VTC-2200 | 2200 GPM | Call for Details | 152,000 | Above/Below/Flush |