Poultry Crate Washing System

Poultry Crate Washing System for the Food Processing Industry – Sanitation Application

The Challenge

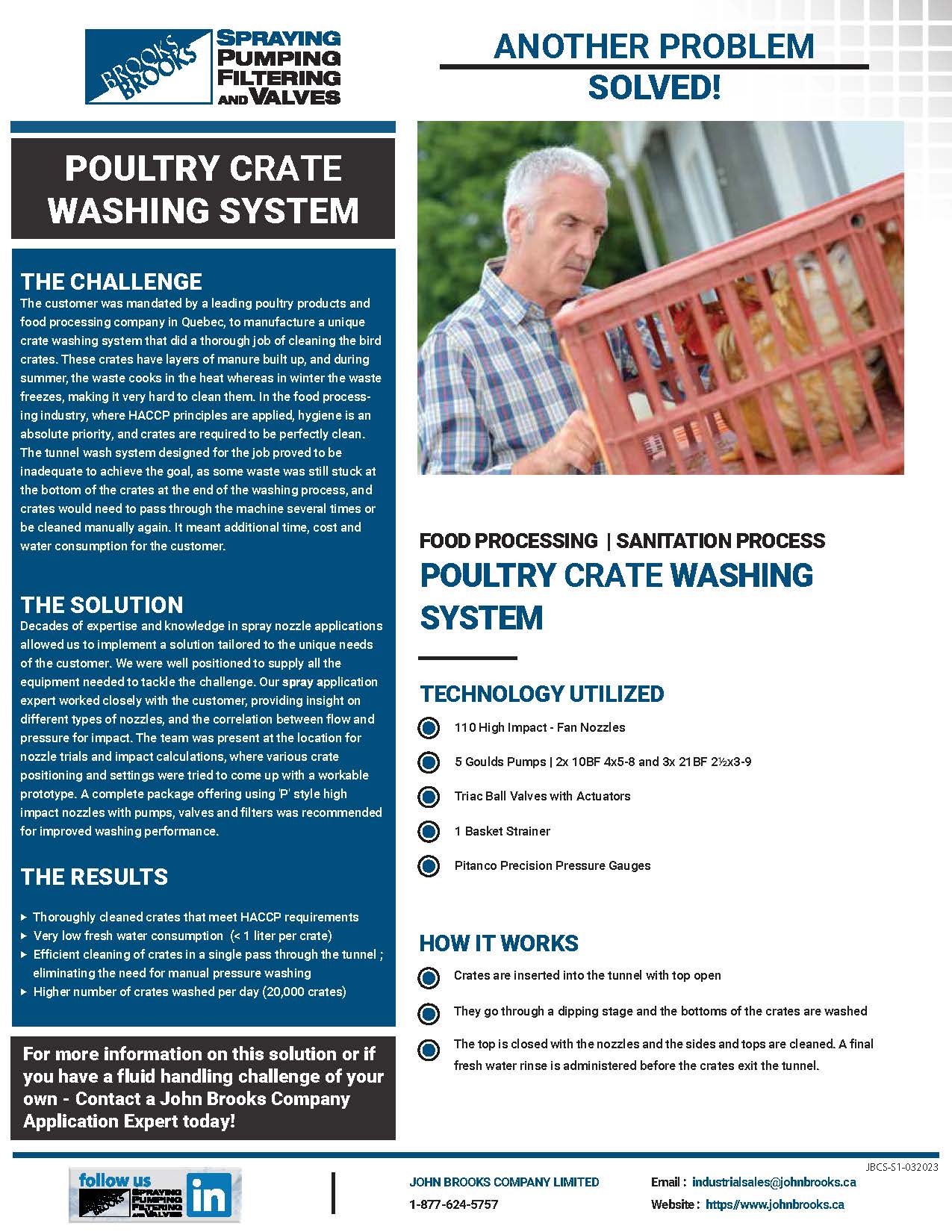

The customer was mandated by a leading poultry products and food processing company in Quebec, to manufacture a unique crate washing system that did a thorough job of cleaning the bird crates. These crates have layers of manure built up, and during summer, the waste cooks in the heat whereas in winter the waste freezes, making it very hard to clean them. In the food processing industry, where HACCP principles are applied, hygiene is an absolute priority, and crates are required to be perfectly clean.

The tunnel wash system originally designed for the job proved to be inadequate to achieve the goal, as some waste was still stuck at the bottom of the crates at the end of the washing process, and crates would need to pass through the machine several times or be cleaned manually again. It meant additional time, cost and water consumption for the customer.

The Solution

Decades of expertise and knowledge in spray nozzle applications allowed us to implement a solution tailored to the unique needs of the customer. We were well positioned to supply all the equipment needed to tackle the challenge. Our spray application expert worked closely with the customer, providing insight on different types of nozzles, and the correlation between flow and pressure for impact. The team was present at the location for nozzle trials and impact calculations, where various crate positioning and settings were tried to come up with a workable prototype. A complete package offering using ‘P’ style high impact nozzles with pumps, valves and filters was recommended for improved washing performance.

The Results

- Thoroughly cleaned crates that meet HACCP requirements

- Very low fresh water consumption (< 1 liter per crate)

- Efficient cleaning of crates in a single pass through the tunnel eliminating the need for manual pressure washing

- Higher number of crates washed per day (20,000 crates)

Technology Utilized

- 110 High Impact Fan Nozzles

- 5 Goulds Pumps

- 1 Basket Strainer

- Pitanco Precision Gauges

How it Works

- Crates are inserted into the tunnel with top open

- They go through a dipping stage and the bottoms of the crates are washed

- The top is closed with the nozzles and the sides and tops are cleaned.

- A final fresh water rinse is administered before the crates exit the tunnel.

Resources

Talk to one of our Experts

Reach out to our team of Spraying, Pumping, Filtering, Valve, and Systems Specialists today. We know we can help you with any municipal or industrial application challenges.