Improved Food Product Quality with Hygienic Pumps from Wilden

Wilden Saniflo Hygienic Pumps for Improved Food Product Quality

The Challenge

A well-known condiment manufacturer had issues with the FDA AODD pump that transferred its product from 45-gallon drums to the kettle. Their chow sauce ingredients got crushed during the transfer, which changed their recipe and quality of the finished product. The ball and check design pump frequently jammed, causing unscheduled downtime and production loss, resulting in higher maintenance costs.

The Solution

Our pump application expert visited the Customer to review the application and discuss all related issues, including regulatory compliance, quality and maintenance issues, and the long cleaning time required. The Wilden® 2″ AODD Saniflo™ Hygienic™ Flap Valve Design Pump with Swivel Stand was recommended and purchased. This pump’s low-shear operation ensures the product is not damaged, preserving the ingredients’ integrity and would keep the food from being hung up and captured, decreasing product waste. The Saniflo™ pump has connections for easy assembly, disassembly, and clean-in-place (CIP) capabilities.

- Improved Product Quality

- Eliminated Clogging

- Increased Production

- Reduced Service & Maintenance Costs

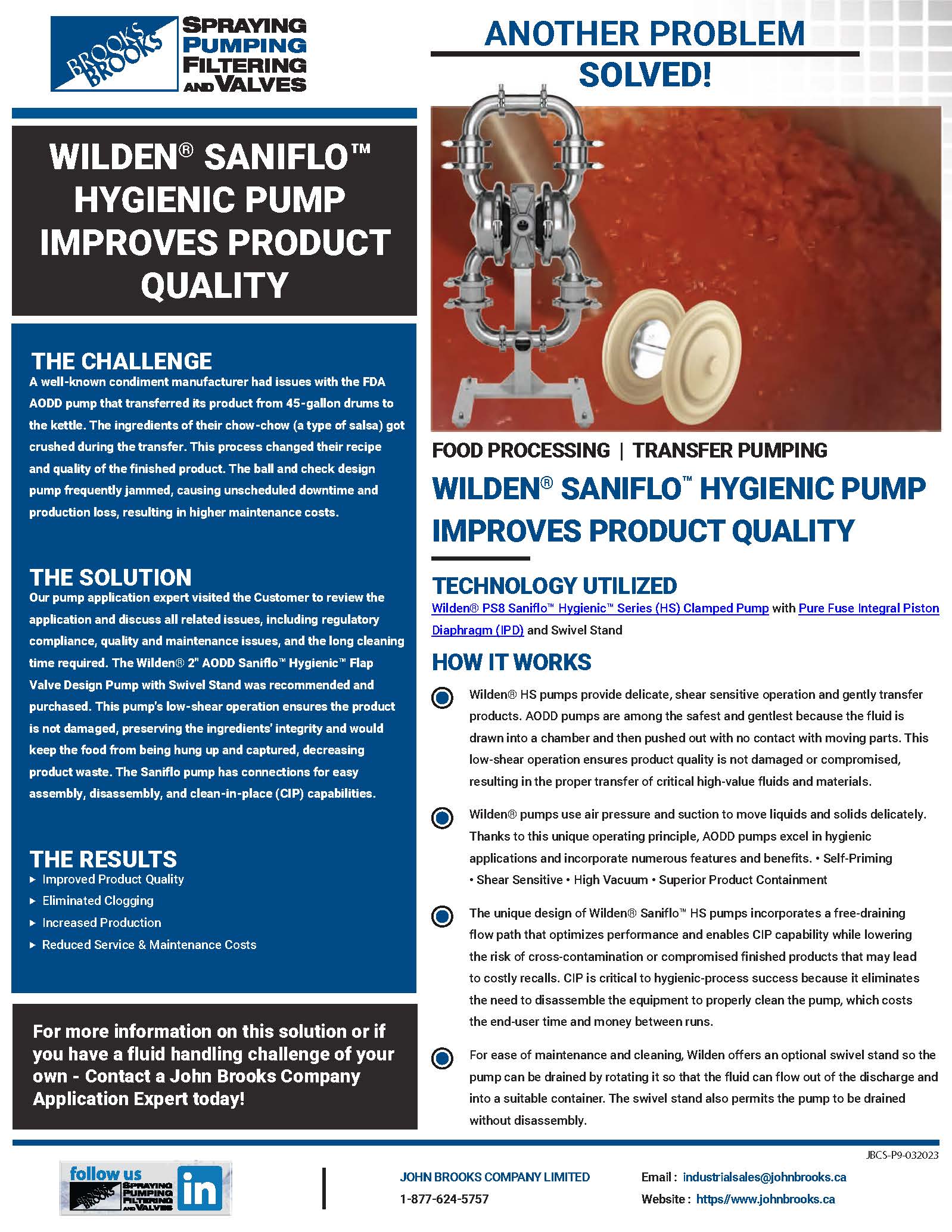

Technology Utilized

Wilden PS8 Saniflo Hygienic Series( HS) Clamped Pump with Swivel Stand

How it Works

- Wilden® HS pumps provide delicate, shear-sensitive operation and gently transfer products. AODD pumps are among the safest and gentlest because the fluid is drawn into a chamber and then pushed out with no contact with moving parts. This low-shear operation ensures product quality is not damaged or compromised, resulting in the proper transfer of critical high-value fluids and materials.

- Wilden® pumps use air pressure and suction to move liquids and solids delicately. Thanks to this unique operating principle, AODD pumps excel in hygienic applications and incorporate numerous features and benefits – Self-Priming, Shear Sensitive, High Vacuum, and Superior Product Containment.

- The unique design of Wilden® Saniflo™ HS pumps incorporates a free-draining flow path that optimizes performance and enables CIP capability while lowering the risk of cross-contamination or compromised finished products that may lead to costly recalls. CIP is critical to hygienic-process success because it eliminates the need to disassemble the equipment to properly clean the pump, which costs the end-user time and money between runs

- For ease of maintenance and cleaning, Wilden offers an optional swivel stand so the pump can be drained by rotating it so that the fluid can flow out of the discharge and into a suitable container. The swivel stand also permits the pump to be drained without disassembly.

Resources

Talk to one of our Experts

Reach out to our team of Spraying, Pumping, Filtering, Valve, and Systems Specialists today. We know we can help you with any municipal or industrial application challenges.