Wilden Chem-Fuse Diaphragm Pumps for Filter Press Pumping

Filter Press Pumping Optimized with Wilden Chem-Fuse IPDs

The Challenge

The customer used AODD pumps to pump potato starch into their filter press. The potato starch is very abrasive and hard on the pumps causing constant pump failure. The customer often replaced pumps, pump parts, diaphragms, shafts, etc. The downtime and replacement costs were expensive.

The Solution

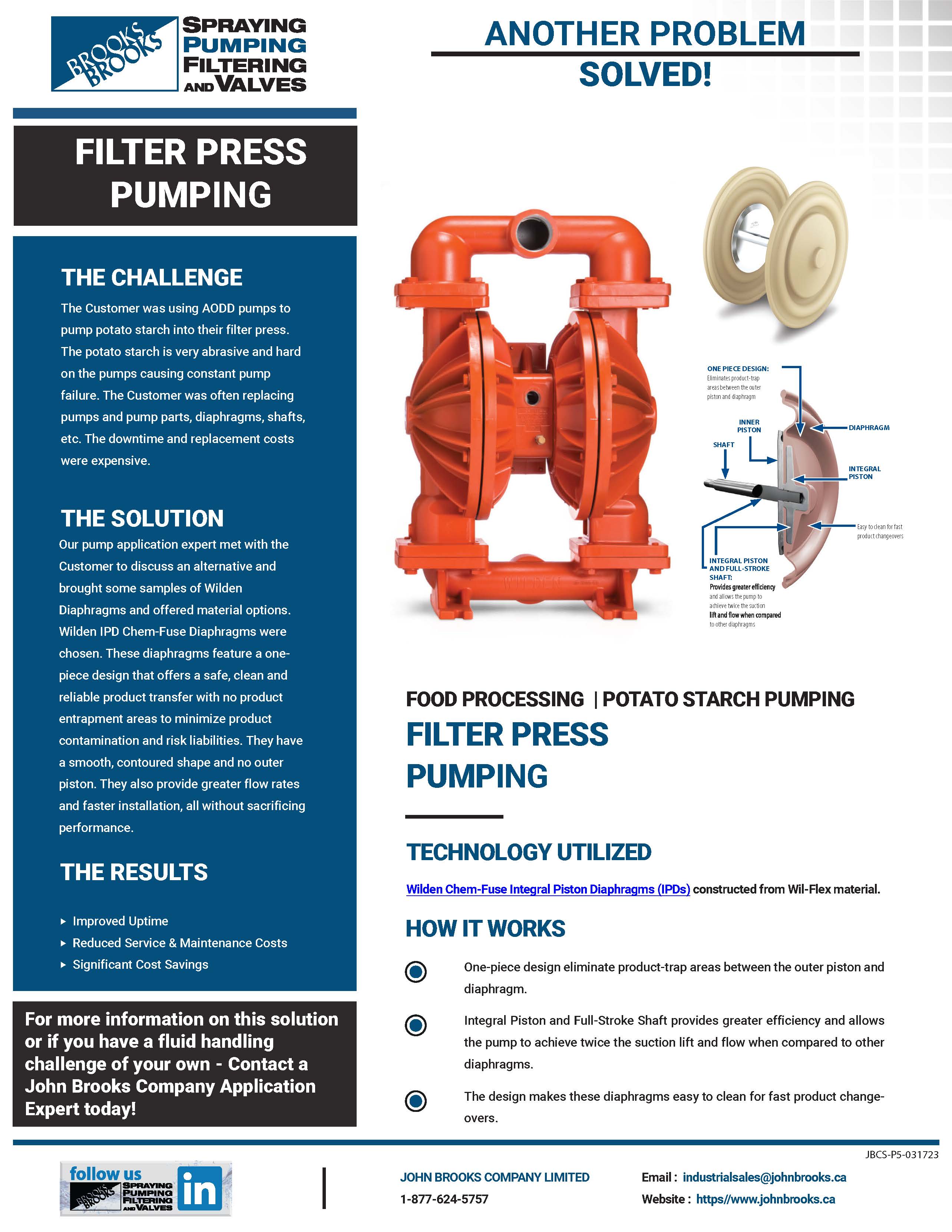

Our pump application expert met with the customer to discuss an alternative, brought some Wilden Diaphragms samples, and offered material options. Wilden IPD Chem-Fuse Diaphragms were chosen. These diaphragms feature a one-piece design that provides a safe, clean and reliable product transfer with no product entrapment areas to minimize product contamination and risk liabilities. They have a smooth, contoured shape and no outer piston. They also provide greater flow rates and faster installation, all without sacrificing performance.

The Results

- Improved Uptime

- Reduced Service & Maintenance Costs

- Significant Energy Savings

Technology Utilized

Wilden Chem-Fuse Integral Piston Diaphragms (IPDs) constructed from Wil-Flex material.

How it Works

- The one-piece design eliminate product-trap areas between the outer piston and diaphragm.

- Integral Piston and Full-Stroke Shaft provides greater efficiency and allows the pump to achieve twice the suction lift and flow compared to other diaphragms.

- The design makes these diaphragms easy to clean for fast product changeovers.

Resources

Talk to one of our Experts

Reach out to our team of Spraying, Pumping, Filtering, Valve, and Systems Specialists today. We know we can help you with any municipal or industrial application challenges.