.png?width=900&name=Untitled%20design%20(2).png)

Spray drying is a transformative method in powder production, efficiently converting liquid or slurry solutions into finely crafted dry powders. The process uses hot gas or air to dry the liquid, turning it into tiny drops and removing the solvent. The resulting powder is meticulously collected and prepared for various applications, including food and beverage, pharmaceuticals, and ceramics.

Understanding Spray Drying: Efficiency and Precision

Spray drying makes even, powder-like substances with the desired size distribution. This method is excellent for drying heat-sensitive materials. The quality of the final product relies on several crucial factors.

The components include the atomizer or spray nozzle type, temperatures, airflow, slurry consistency, and drying chamber size and shape. The process typically involves specialized equipment like a spray dryer.

The Evolution of Atomization: A Focus on Nozzles

Atomization, the process of converting liquid feed into droplets for drying in the hot air stream, is fundamental to spray drying. The choice of nozzle type plays a crucial role in determining the quality and characteristics of the final powder product. These are the most common types of spray drying nozzles that have revolutionized the atomization process.

Hydraulic Nozzles: Precision and Performance

Hydraulic nozzles use fast rotation and high-pressure flow to create small droplets, perfect for thin liquids. BETE’s innovative design, like the Twist & Dry Spray Dry Nozzle, ensures optimal and reliable performance, enhancing the spray drying process.

Two-Fluid Nozzles: Control and Versatility

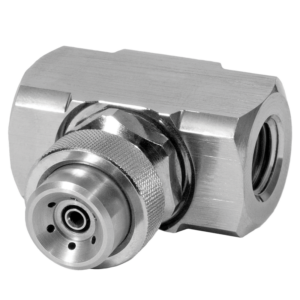

Two-fluid nozzles utilize two fluid streams—one for atomization and the other for the required pressure. Predominantly used for high-viscosity liquids, these nozzles provide precise control over droplet size. The XAER dual fluid nozzle is a reliable choice for effectively spraying liquids that are over 100 centipoises.

Choosing the Right Nozzle: A Blend of Science and Efficiency

Choosing the right spray dry nozzle depends on the liquid's thickness, desired droplet size, and product requirements. The nozzle design affects energy use during drying. Choosing the proper nozzle is crucial for efficiency and top-quality products.

Embrace Innovation with Twist & Dry: Simplifying Maintenance and Performance

The Twist & Dry (TD) is a state-of-the-art spray dry nozzle solution engineered by BETE. TD enhances maintenance ease and offers tailored design adaptability to meet precise application needs. Its exclusive patented locking mechanism securely locks the swirl and orifice within the carrier during assembly and replacement, streamlining installation. This innovation makes replacing worn nozzle parts in the dryer lance easier, simplifying spray dryer maintenance for experienced operators.

Advantages of utilizing TD spray dry nozzle technology include:

- It offers over 1,000 switchable combinations tailored to your flow rate and spray angle requirements.

- It uses a patented locking lug feature that firmly secures swirl and orifice without requiring additional parts.

- Demonstrates resistance to clogs, ensuring a smooth operational experience.

- The nozzle body construction uses 218SS material, effectively preventing galling.

- Capable of functioning at pressures as high as 10,000 psi (with high-temperature performance rated for 7,000 psi at 800°F).

- You can quickly assemble the body and carrier without requiring specialized tools.

- Substitute swirls and discs are easily available for quick shipment.

Spray drying varies, so the Twist & Dry system adapts with four components for diverse needs.

- The TD Nozzle Series makes maintenance and installation easy with its patented locking lug feature and clog resistance.

- TDL nozzles are small and effective. They have lower flow rates and are suitable for smaller applications and testing. However, they still maintain all the advantages of TD nozzles.

- The TD-K Nozzle Series caters to high-pressure applications. These nozzles can withstand up to 10,000 psi. The PEEK backup rings equip them.

- The TD-HT Nozzle Series can withstand high temperatures of up to 800°F. These spray dry nozzles have a unique body and carrier design that utilizes metal gaskets instead of O-rings.

To achieve the best powder production results, understanding spray drying and the importance of spray dry nozzles is crucial. The advanced Twist & Dry spray dry nozzle technology improves efficiency, precision, and reliability in spray drying across industries.

JOHN BROOKS COMPANY IS YOUR PRIME SOURCE FOR Spray Nozzles

John Brooks Company partners with world-renowned manufacturers to offer a variety of spray nozzles for a broad range of commercial, municipal, and industrial uses, such as agriculture, food production, oil and gas, and mining. Our experts are available to assist you in selecting the right spray nozzle for your specific requirements.

Contact us now to explore what we have to offer or speak to one of our specialists.