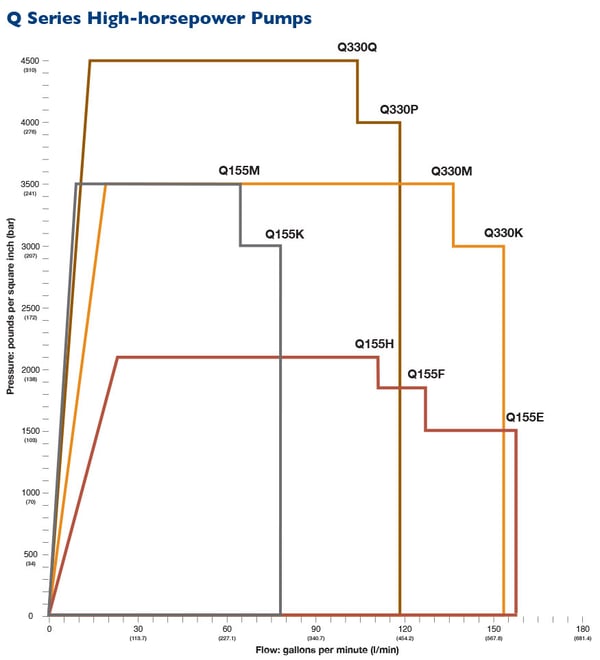

Hydra-Cell Q Series Overview & Selection

|

|

| Q155 Series Low Pressure | Q155 Series Medium Pressure |

| Max Flow: 157 gpm (595 l/min) 5383 BPD Max Pressure: 2100 psi (145 bar) |

Max Flow: 78 gpm (295 l/min) 2674 BPD Max Pressure: 3500 psi (241 bar) |

|

|

| Q330 Series Medium Pressure | Q330 Series High Pressure |

| Max Flow: 153 gpm (579 l/min) 5247 BPD Max Pressure: 3500 psi (241 bar) |

Max Flow: 117 gpm (442 l/min) 4011 BPD Max Pressure: 4500 psi (310 bar) |

Hydra-Cell Q Series Pumps Design Advantages

T Series and Q Series pumps feature the Hydra-Cell seal-less design, eliminating cleanup costs from leaking seals or packing and protecting operators from dangerous fluids such as those containing hydrogen sulfide (Q155 shown).

Exclusive Seal-less Diaphragm Design

- Seal-less design separates the power end from the process fluid end, eliminating leaks, hazards, and the expense associated with seals and packing

- Low NPSH requirements allow for operation with a vacuum condition on the suction - positive inlet pressure is not necessary

- Can operate with a closed or blocked suction line and run dry indefinitely without damage, eliminating downtime and repair costs

- Unique diaphragm design handles more abrasives with less wear than gear, screw or plunger pumps

- Hydraulically balanced diaphragms to handle high pressures with low stress

- Provides low-pulse, linear flow due to its multiple diaphragm design

- Lower energy costs than centrifugal pumps and other pump technologies

- Rugged construction for long life with minimal maintenance

- Compact design and double-ended shaft provides a variety of installation options

| Maximum Capacity | Maximum Discharge Pressure | Maximum Inlet Pressure | Maximum Operating Temperature | |||||

| Model | (gpm) | (l/min) | (psi) | (bar) | (psi) | (bar) | (F)* | (C)* |

| Q155E | 157 | 595 | 1500 | 103 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q155F | 127 | 490 | 1850 | 128 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q155H | 111 | 421 | 2100 | 145 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q155K | 78 | 295 | 3000 | 207 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q155M | 63 | 238 | 3500 | 241 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q330K | 153 | 579 | 3000 | 207 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q330M | 136 | 514 | 3500 | 241 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q330P | 118 | 446 | 4000 | 276 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q330Q | 104 | 393 | 4500 | 310 | 500 | 34 | 180 ̊ | 82.2 ̊ |

________________________________________________________________________________________________________________________

Hydra-Cell Pumps for Mining, Tunneling, Quarrying & Dust Suppression

Applications by Mining Market

- Borehole Stabilization (Injecting bentonite and other substances)

- Liquid Explosives (Charging liquid explosives into blast holes and rigs)

- Drill Head Cooling (Cooling the picks and coal cutters and tunneling machines while reducing dust generation)

- Hazardous Chemical Pumping (Metering hazardous solutions in metal extraction)

- Conveyor Cleaning (24/7 continuous duty in high-pressure jet cleaning)

- Gland Seal Flushing (Protecting large slurry pumps from seal damage)

- Gas Extraction (Powering a Venturi jet pump to lift drillhole water and release gas to the surface)

Have a Fluid Handling Problem? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.