Hydra-Cell Metering Pumps Overview & Selection

________________________________________________________________________________________________________________________

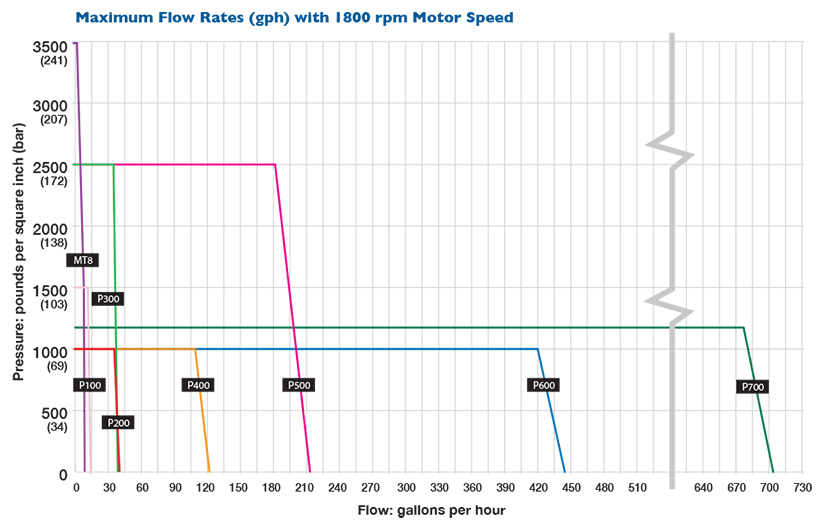

Flows shown in the graph above and listed in the chart below for each metering pump are based upon lab testing of multiple pumps. However, flows listed are approximate values and pumps must be calibrated once installed into any system. Flow variations will occur, but calibration will ensure proper pump performance.

| Motor Speed rpm | Maximum Capacity gph | Maximum Discharge Pressure psi (bar) | Maximum Operating Temperature F (C)3 | Maximum Inlet Pressure psi (bar) | |||

| Model1 | Non-metallic2 | Metallic | Non-metallic | Metallic | |||

| MT8 | 1800 | 8.0 | 350 (24) | 3500 (241) | 140˚(60˚) | 250˚(121˚) | 500 (34)4 |

| P100 | 1800 | 13.5 | 350 (24) | 1500 (103) | 140 ̊ (60 ̊) | 250 ̊ (121 ̊) | 250 (17) |

| P100 | 3600 | 27.0 | 350 (24) | 1500 (103) | 140 ̊ (60 ̊) | 250 ̊ (121 ̊) | 250 (17) |

| P200 | 1800 | 40.5 | 350 (24) | 1000 (69) | 140 ̊ (60 ̊) | 250 ̊ (121 ̊) | 250 (17) |

| P200 | 3600 | 81.0 | 350 (24) | 1000 (69) | 140 ̊ (60 ̊) | 250 ̊ (121 ̊) | 250 (17) |

| P300 | 1800 | 40.6 | N/A | 2500 (172) | N/A | 250 ̊ (121 ̊) | 500 (34) |

| P300 | 3600 | 81.4 | N/A | 2500 (172) | N/A | 250 ̊ (121 ̊) | 500 (34) |

| P400 | 1800 | 121.1 | 350 (24) | 1000 (69) | 140 ̊ (60 ̊) | 250 ̊ (121 ̊) | 250 (17) |

| P400 | 3600 | 242.8 | 350 (24) | 1000 (69) | 140 ̊ (60 ̊) | 250 ̊ (121 ̊) | 250 (17) |

| P500 | 1800 | 212.8 | N/A | 2500 (172) | N/A | 250 ̊ (121 ̊) | 500 (34) |

| P500 | 3600 | 425.9 | N/A | 2500 (172) | N/A | 250 ̊ (121 ̊) | 500 (34) |

| P600 | 1800 | 444.8 | 350 (24) | 1000 (69) | 140 ̊ (60 ̊) | 250 ̊ (121 ̊) | 250 (17) |

| P600 | 3600 | 890.3 | 350 (24) | 1000 (69) | 140 ̊ (60 ̊) | 250 ̊ (121 ̊) | 250 (17) |

| P700 | 1800 | 706 | N/A | 1200 (83) | N/A | 250 ̊ (121 ̊) | 250 (17) |

| P700 | 3600 | 1394 | N/A | 1200 (83) | N/A | 250 ̊ (121 ̊) | 250 (17) |

1 Ratings are for X-cam design.

2 350 psi (24 bar) maximum with PVDF or PVC (MT8 only) liquid ends; 250 psi (17 bar) maximum with Polypropylene liquid end (P Series only).

3 Consult factory for correct component selection for temperatures from 160˚F (71˚C) to 250˚F (121˚C).

4 300 psi (20 bar) maximum with non-metallic MT8 models.

Hydra-Cell Metering Pumps Design Advantages

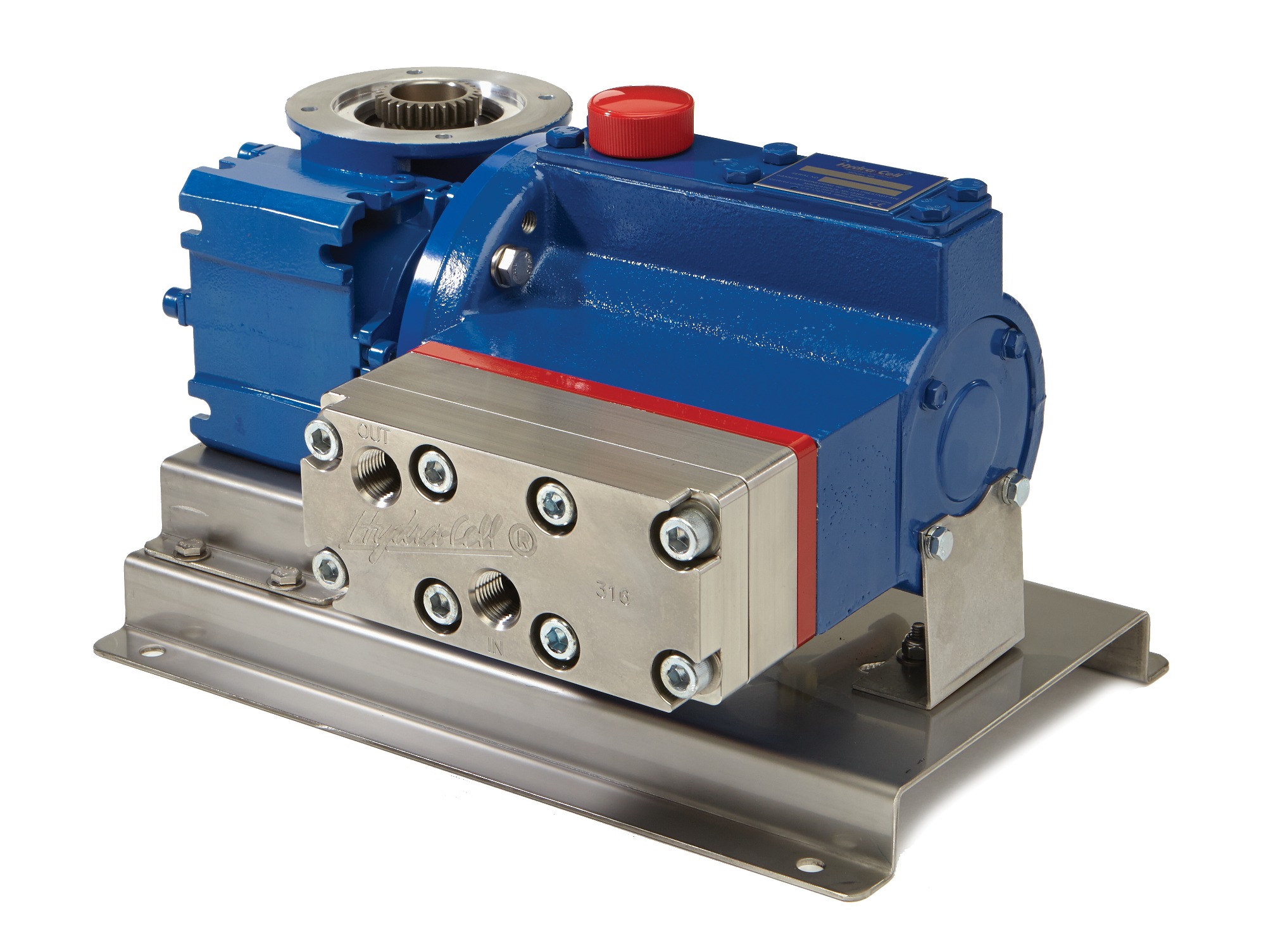

Compact, cost-effective pump systems for high-performance metering applications.

The technology used to produce metering pumps has barely changed in over a generation. As a result, conventional metering pumps have operational limitations 30-Day and greater cost consequences. Shelf-Life! Hydra-Cell is not a conventional metering pump. Hydra-Cell Metering Solutions pumps enable you to meet and, in most cases, exceed API 675 performance standards with virtually pulse-less, linear flow while providing many other operational benefits.

Taking advantage of the most current technologies, Hydra- Cell P Series pumps achieve superior levels of accuracy, repeatability and linearity, while delivering precise, constant flow. This revolution in metering employs the latest available means of electronic flow control to replace antiquated, inaccurate stroke adjusters.

To maintain accuracy in a hydraulically-actuated metering pump, the volume of oil on the non-process side of the diaphragm must remain constant. To maintain accuracy in a hydraulically-actuated metering pump, the volume of oil on the non-process side of the diaphragm must remain constant. Conventional metering pumps rely on vacuum sensing or mechanical activation to compensate for leakage past the plunger. They may not compensate on every pump stroke.

Hydra-Cell pumps incorporate a replenishment valve in every piston assembly. This ensures optimum actuating oil volume on every diaphragm stroke to provide superior accuracy that exceeds the performance demands of API 675.

Hydra-Cell pumps incorporate a replenishment valve in every piston assembly. This ensures optimum actuating oil volume on every diaphragm stroke to provide superior accuracy that exceeds the performance demands of API 675. In addition, the modern design features of the Hydra-Cell pump lower your acquisition costs when compared to conventional metering pumps, and its inherently simple yet elegant engineering keeps your maintenance and replacement costs down. Rugged construction and long- lasting durability will provide economy and value over the lifetime of your Hydra-Cell metering system.

Used in place of conventional metering pumps to provide Honorable Mention superior performance at a lower cost, Hydra-Cell is an extraordinary metering pump built to handle your precise metering and dosing applications.

| Linear "Pulse-less" Metering with the Hydra-Cell MT8 Pump | What is a Metering Pump? |

Hydra-Cell Metering Pumps are NOT Conventional

Accurate, Reliable Electronic Flow Control

Unlike metering pumps that use manual stroke adjusters, Hydra-Cell P Series metering pumps use Variable Frequency Drive (VFD) electronic flow adjustment to maintain greater accuracy over the entire turndown range. This reduces the possibility of operator error, pumping inaccuracies, lost motion, and chance of leakage.

- Solid-state electronics are unlikely to fail

- Metering is linear over the entire range

- Volume per stroke is constant and a known value

- Easy calibration of the desired feed rate

- Rate of change is virtually instantaneous (0 to maximum rpm in 0.3 seconds) with AC motor

Achieve Economy with Technology

Hydra-Cell metering pumps combine simple, elegant engineering with rugged construction to offer greater versatility while lowering overall costs.

- Smaller footprint with the same capability as larger pumps lowers acquisition costs and saves valuable space in the facility

- Each model covers an extensive range of pressures and flows – no need for different plunger and liquid end sizes to accommodate increases

- Inherent simplicity of the Hydra-Cell design allows versatile application compared to complex metering pumps that may require expensive construction changes to meet specific needs

- Lower parts and maintenance costs

- Separate gearbox makes it easy to change applications while preventing cross-contamination of actuating oil

- Multiplexing capability enables mixing ratios of multiple fluids in flexible, economical ways

Greater Choice of Materials Enhances Capability

Some metering pump manufacturers offer only PTFE diaphragms, which require more frequent and costly replacement due to stress and low processing temperatures.

Hydra-Cell metering pumps can be equipped with a variety of diaphragm materials (FKM, Buna-N, EPDM, Neoprene,Aflas, and PTFE).This enables Hydra-Cell metering pumps to operate over a wider range of processing applications.

In addition, several Hydra-Cell metering pump packages are available with special materials such as Hastelloy C and PVDF. Other metering pumps apply substantial price adders for exotic liquid end materials.

Accurate Metering and Dosing with Virtually Pulse-less Flow

Reduced Pulsations Improve Operation

Pulsing, surging flow from traditional metering pumps can produce greater strain on the system and more wear and tear on the pump. Hydra-Cell features a multiple-diaphragm design (except model P100) that practically eliminates pulsations.

- Reduces pipe strain

- Enhances operating safety

- Minimizes maintenance

- Reduces friction and acceleration losses in the suction line

- Eliminates the need for pulsation dampeners

- Provides accurate metering with linear, constant flow

- Lowers system acquisition costs

Pulsation Graph Comparison

Compared to conventional metering pumps operating under the same conditions at the same flow and pressure, Hydra-Cell metering pumps provide smooth, almost pulse-less performance. This allows for the design of a safer, less expensive metering pump system and for use in more accurate applications, such as spraying which cannot tolerate pulsing flow.

The multiple-diaphragm design of Hydra-Cell metering pumps provides virtually pulse-less, linear flow without the need for expensive pulsation dampeners.

The IChemE Awards recognize innovation and excellence in making outstanding contributions to safety, the environment, and sustainable development in the chemical and bioprocess industries.

________________________________________________________________________________________________________________________

Hydra-Cell Pumps for Mining, Tunneling, Quarrying & Dust Suppression

Applications by Mining Market

- Borehole Stabilization (Injecting bentonite and other substances)

- Liquid Explosives (Charging liquid explosives into blast holes and rigs)

- Drill Head Cooling (Cooling the picks and coal cutters and tunneling machines while reducing dust generation)

- Hazardous Chemical Pumping (Metering hazardous solutions in metal extraction)

- Conveyor Cleaning (24/7 continuous duty in high-pressure jet cleaning)

- Gland Seal Flushing (Protecting large slurry pumps from seal damage)

- Gas Extraction (Powering a Venturi jet pump to lift drillhole water and release gas to the surface)

Have a Fluid Handling Problem? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.