BETE provides a wide variety of high-performance spray nozzles and automated spray systems for coating applications. Our precision spray technology minimizes waste and overspray and ensures the even application of the spray media.

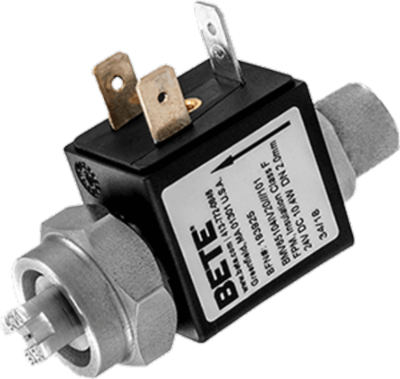

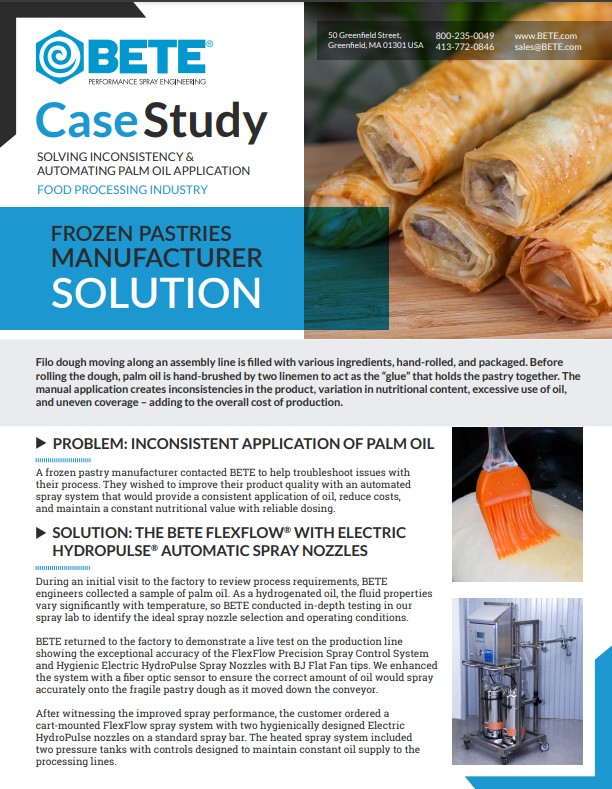

BETE spray nozzles are used throughout the food industry to apply ingredients to foods, spray antimicrobials on meat and poultry, and mold inhibitors to cheeses and baked goods. Use oil sprayer systems for spraying release agents on trays and molds to prevent sticking. BETE’s Electric HydroPulse automatic nozzles’ hygienic design for the food industry delivers uniform spray coverage with minimal waste through precise intermittent spraying.

Many industrial coating applications use spray nozzles to apply glues and resins to building materials, perfumes and lotions to tissues and fabric softeners, and flame retardants to textiles.

Our automated spray coating systems, like the BETE FlexFlow Precision Spray Control Systems, ensure precision spray control and flexible automation for coating and lubricating, which improves product quality while saving resources.

Customers can trust BETE Spray Nozzles and BETE Sprayer Systems to provide a high-quality coating for their spray applications.

BETE Spray Nozzles Common Uses & Industries

- Spraying egg wash, oil, or butter onto dough

- Moistening for seed adhesion

- Applying flavorings, preservatives, antimicrobials, and mold inhibitors to food products and packaging

- Applying dyes, disinfectants, perfumes, lotions, and softeners to papers and tissue products

- Adding water or moisture to beef patties before freezing to maintain weight and improve cooking

- Spraying release agents or oils to molds and trays to prevent sticking

- Coating steel parts with lubricants and corrosion inhibitors

- Spraying glue onto parts before assembly

- Applying hydrophobic solutions to roof tiles

- Food and Beverage Processing Industry

- Building Materials Industry

Important Factors to Consider When Selecting a BETE Spray Nozzle For Precision Coating Applications

When looking to optimize precision coating applications, choosing the right nozzle is paramount. Understanding the key factors ensures that BETE Spray Nozzles deliver optimal performance in your coating processes. Here are the important factors to consider when selecting a nozzle for precision coating applications:

- Speed of conveyor

- Shape of products

- Required coverage

- Spray media density and viscosity

- Ease of maintenance/replacement

- Available nozzle mounting locations and required nozzle throw

- Available/required flow rate and coverage densities

- Available pressure drop (∆P) across the nozzle

∆P = supply pressure at nozzle inlet - process pressure outside nozzle