Customized Mixer Solutions for your Mixing Needs

________________________________________________________________________________________________________________________

Mixers for The Mining & Mineral Processing Industries

Dynamix was borne out of the extreme demands of the mineral processing industry. Our high-performance mixers are backed by robust design and engineering mixing principles. From rugged processes to corrosive applications, our mixers can endure your most challenging mining processes.

|

|

|

Slurry Abrasion

|

Protection

|

High Temperature

|

DYNAMIX Solution:

Mining mixers must be able to withstand extreme applications and conditions and rugged processes such as ore slurrification, solid/liquid separations in decantation and attrition scrubbing involving corrosive chemicals, abrasive minerals and acidic wastewater byproducts.

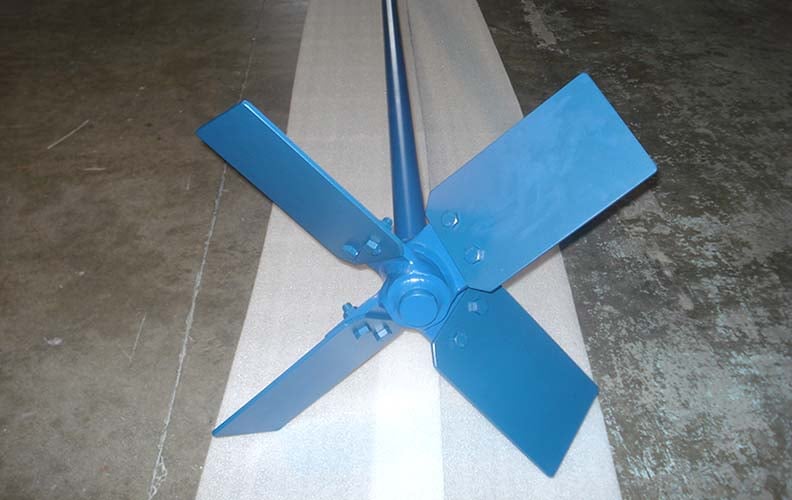

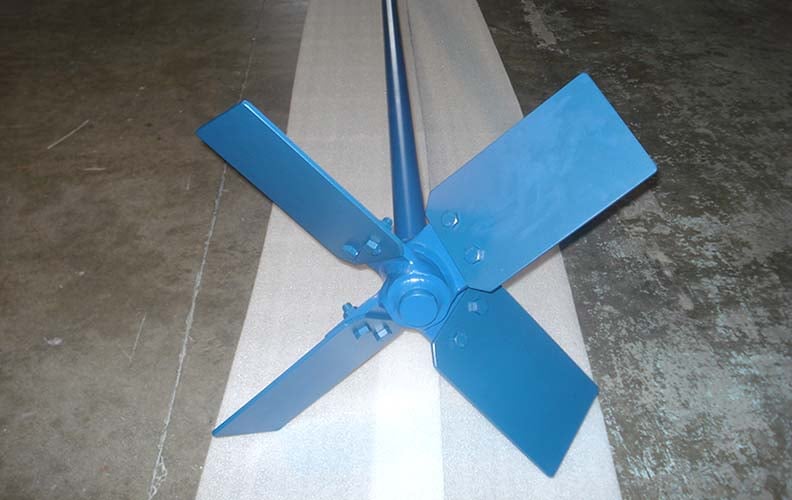

Coated Impellers - PVDF Coatings, Rubber Coatings, Teflon Coatings & More

Dynamix can incorporate a wide variety of abrasion resistant coatings to the wetted parts, e.g., rubber coatings, PVDF coatings, or Teflon coatings, and more. These coatings reduce friction and extend the life of your mixer in application. Select mining processes and applications that use corrosive chemicals require expert input in designing a solution to ensure equipment is not damaged in such challenging mixing environments.

Rubber Coating for Impeller Blades

Customized Mixers for your Mining Project

Work with our mining mixer experts to design a heavy-duty mixer for your mining and refining project: from ore leaching, to counter current decantation, to flotation, to conditioning, and attrition scrubbing processes, and more.

- Counter Current Decantation

- Ore Leaching

- Ore Conditioning

- Attrition Scrubbers

- Atmospheric Digestion

- Absorption & Solvent Extraction Circuits

- Pressure Oxidation

- Slurry Make Down

- Reagent & Waste Treatment

- Lime Neutralization

- Coagulation

- Chemical Precipitation

- Brine Reactors

- Cyanide Decomposition

- Primary & Secondary Stage Flocculation

|

|

PVDF Coating - Wetted Parts |

Rubber Coatings for Impellers |