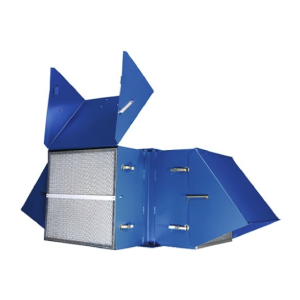

Dollinger AI-187 Single Stage

The Dollinger AI-187 single stage air intake filter is designed to efficiently and economically remove dust, dirt and other airborne contaminants from the atmosphere in a single stage panel filter element protecting diesel and gas engines, blowers, axial compressors and small turbines and, at the same time, reducing inlet noise.

Dollinger manufactures 18 standard models, available with ranges from 3000 to 72,000 SCFM and bottom outlets ranging in size from 6″ to 36″ in diameter. The optional silencing feature provides sound attenuation up to 16 dB(A).

Housing Design and Construction

The rigid, all weather galvannealed housing of the AI-187 provides strength of the AI-187 provides strength and corrosion resistant protection on outdoor installations. All surfaces are finished with a coat of blue hammertone enamel for long life and durability. Weatherhoods are provided as standard equipment.

All metal joints of the AI-187 are welded and caulked as required to prevent dust from entering the unit. The standard conical safety screen over the filter outlet prevents small foreign objects from entering the exposed air intake passage when servicing or replacing panel elements. A ¼” pressure tap attachment is standard on each housing for ease of installation.

The filter housing may also be modified or customized to meet special application needs.

Element Design and Construction

The single-panel element design of the Dollinger AI-187 provides clean air with low pressure loss and high efficiency. No special tools or parts are required to replace or service Dollinger panel elements. A pull strap provided across the face of each element allows fast and simple change out.

The panel element incorporates a pleated media design which provides optimum filtration area with minimum pressure loss and large dirt holding capacity. An electrogalvanized steel frame and synthetic fiber filter medium combine to make the element cleanable and reusable. A rugged metal frame and wire mesh guards on the element face provide added durability and ensure against rough handling and moisture.

Each panel element of the AI-187 can handle flow rates of 3000 SCFM and provide 99% retention efficiency of 10 microns. After extended use, the elements may be cleaned with a mild detergent solution.

Available Options

When desired, special options and accessories are also available. These include: Silencing for reduction of air and equipment noise, providing sound attenuation up to 16 dB(A); Flange adapters; Top and side outlet designs; Pipe leg supports; Differential pressure gauges; Stainless Steel and Aluminum housing construction; Anti-icing packages; Special finishes to customer required standards. Elements with lower micron ratings and/or higher efficiency ratings are also available.

Panel Filter Element – Element Design Specifications

- Element is panel type, 24″ x 24″ x 2″ nominal.

- Each panel is nominal rated capacity of 3000 SCFM of air.

- Each panel incorporates extended surface medium.

- Efficiency to be 99% of 10 microns.

- Panel is be cleanable type using compressed air or washing with soap and water or mild detergent or shaking by hand.

- Wire screen is installed on upstream face of panel element, expanded metal on downstream face.

- Plastic strap across face of panel for easy removal.

Element Material Specifications

- Panel frame is galvanized.

- Galvanized material is used on upstream face of panel element.

- Medium is polyester.

| PANEL ELEMENT NO. VE – 1113 – 2424 – 517 | |

|---|---|

| Various Panel Ratings (SCFM/Panel) | Initial Pressure Loss (Inches W.C.) |

| 3000 | 0.70 |

| 2500 | 0.50 |

| 2000 | 0.30 |

Wt. = 11 lbs. Each

Tests were conducted in accordance with ASHRAE Standard 52-76 in the Dollinger Research and Development Lab Facility.