BETE is a trusted international spray technology manufacturer for critical chemical processing operations. BETE understands that selecting the correct spray nozzles, lance, injector, or spray system for your chemical process is key to optimizing productivity.

BETE's high-quality spray technology is manufactured with durable and corrosion-resistant materials to perform in the harsh environments found in the chemical processing industry. Materials include nickel alloys and stainless steels for high-temperature environments and plastics for corrosion resistance. Cobalt alloys, silicon carbides, and tungsten carbides offer longevity for use with abrasive spray media.

BETE's customer-focused designers, applications engineers, and sales team work with you to find the best spraying solution for your unique application, whether it be a standard product or a custom design.

Common Applications:

Gas Cooling or Conditioning

Spray Nozzles for Gas Cooling & Conditioning Applications- Nozzles for cooling and quenching in a wide variety of chemical processing applications control process temperatures and protect downstream equipment.

- Cooling process gases prior to scrubber/baghouses

- Cooling combustion exhaust gases

- FGD quench systems

- Emergency quench systems

Gas Scrubbing

- SO2 removal using lime slurries or other scrubbing agents

- Spraying liquids to mask or chemically alter the smell of products, waste, process streams, or exhaust gas

- Acid scrubbers:

- Hydrochloric (HCl), sulfuric acid (H2SO4), nitric (HNO3), or hydrofluoric (HF) acids

- Acid scrubbers:

- Hydrochloric (HCl), sulfuric acid (H2SO4), nitric (HNO3), or hydrofluoric (HF) acids

- Halogen removal:

- Cl2, Br2, F2

- Ammonia/amine scrubbing

- Control NOx emissions using ammonia (NH3) or urea solution

- Nozzles spray ammonia or urea solutions to absorb nitrogen oxides from most combustion processes in which environmental regulations limit emissions.

- A form of gas scrubbing in which the gas passes through a narrowed section of ducting where high velocities help to ensure thorough mixing and contact between the gas and scrubbing fluid

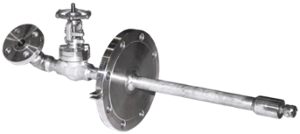

Chemical Injection

Chemical Injection Applications

- Injects various reactants, scavengers, inhibitors, or other chemicals throughout many processes

- BETE can design a custom injection lance specific to your application to ensure proper fabrication, installation, and operation

Tank, Drum, and Tote Cleaning

- Storage tanks

- Reactors

- Process vessels

- Totes

- IBC containers

Tank Mixing & Blending

- Tank circulation

- Solids suspension

- Blending

- Mixing and agitation

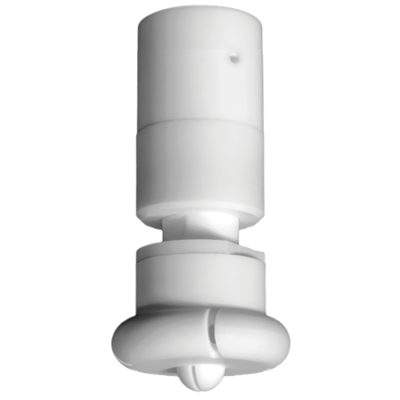

Spray Drying

- Spray drying is unique in producing powders with specific particle size and moisture content regardless of heat and the dryer’s capacity – and the powder quality remains constant during the entire run of the dryer.

- Spray dryer performance is mainly dependent upon the nozzles.

- BETE’s Twist & Dry® nozzle design includes a patented locking system

- Reduces maintenance time and guarantees proper installation for reinstalls

Fire Protection

BETE nozzles are used routinely in dry fire protection systems for:

- Cooling

- Wetting

- Water Wall