3M Amine sweetening equipment are a critical part of the oil and gas processing plant. They significantly impact the overall operating costs of the plant and the plant’s ability to meet sales gas specifications.

Natural gas processing facilities and refineries use treatment solvents to remove acid gas components from gas streams. Amines such as MDEA, DEA, MEA, and specially designed formulations absorb hydrogen sulfide (H2S) and carbon dioxide (CO2) to “sweeten” the gas stream. The use of absolute filtration equipment in Amine Sweetening Processes and the benefits that are provided through efficient filtration of both the recirculating amine stream and the inlet gas to the plant are signicant. The benefits include a notable reduction in contractor plugging and heat exchanger, reboiler, and carbon bed fouling, resulting in lower operating and maintenance costs.

Like every piece of oil and gas field equipment, there are many ways you can get more out of your filtration systems.

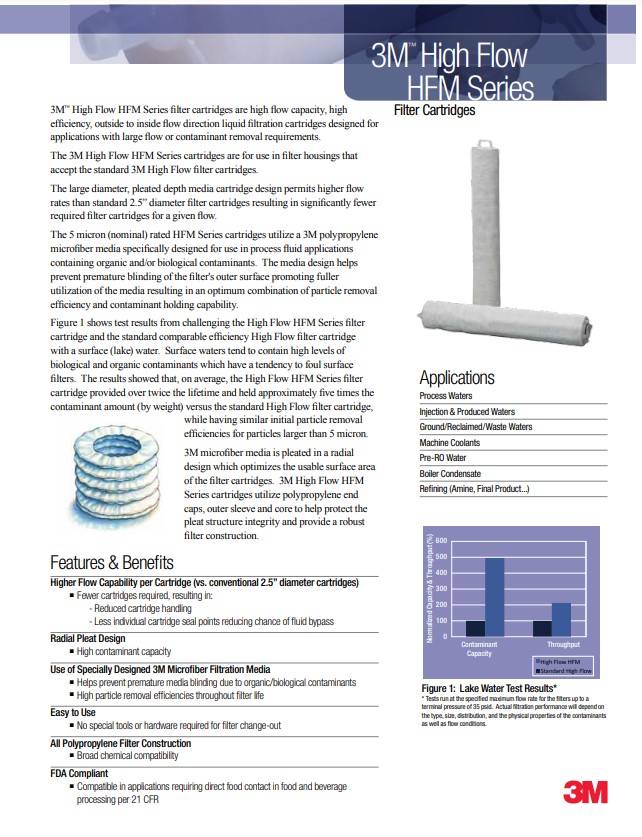

First, choose the right product for the job. There are a wide range of highly specialized filters for various tasks, and because they are purpose designed, they deliver the very best performance.

Pay attention to maintenance, repair and replacement of filters and filtration systems. Trying to squeeze more up-time out of your oil & gas filtration equipment can result in much higher costs when a larger piece of equipment bears the brunt.