1” | 25 mm P220 P230 Pro-Flo Bolted Metal Pumps

Wilden® P220/P230 Pro-Flo Bolted Metal Pumps are also known as FIT, featuring an enhanced flow path design, Wilden’s bolted-construction pumps offer improved flow rates as well as improved diaphragm life. Wilden’s bolted pumps are also designed for superior containment and have the exact bolt down footprint and inlet/discharge connections as Wilden clamped pumps for easy replacement.

P220

NPT or BSPT threaded inlet/discharge liquid connections

P230

DIN or ANSI flanged inlet/discharge liquid connections that don’t require welding or nipple attachment

Wilden P220 P230 Pro-Flo Bolted Metal Pumps Features:

- Widest Array of Chemical Compatibility

- Portable and Submersible

- Large-Solids Passage

- High Suction Lift

- Ease of Operation and Maintenance

- Flexible Internal Adjustment on Manifolds

- Increased On/Off Reliability

- Longest Mean Time Between Repair (MTBR)

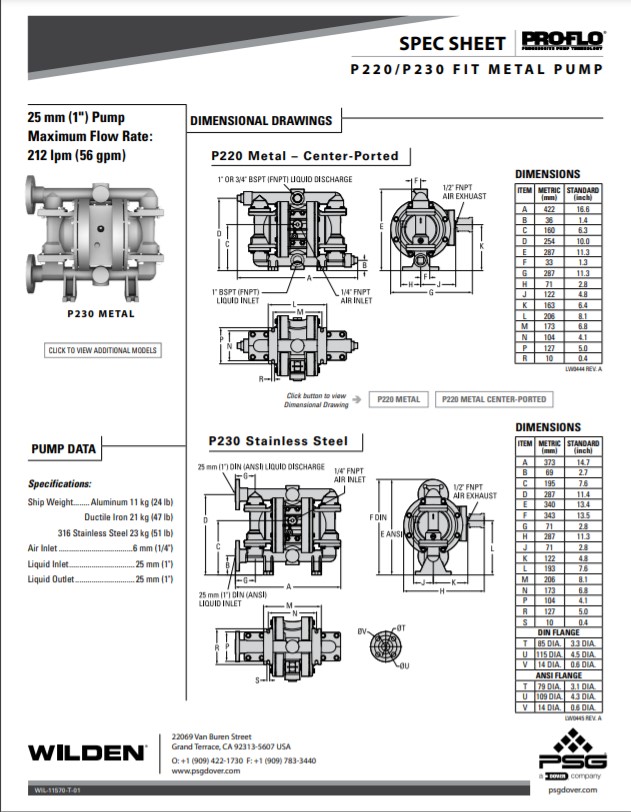

| AIR INLET: | 1/4″ FNPT |

| CONNECTION TYPE: | P220 – NPT/BSPT (Threaded)

P230 – DIN/ANSI (Flanged) |

| MAX PRESSURE: | 125 psi (8.6 bar) |

| LIQUID INLET: | 1″ (25 mm) |

| LIQUID DISCHARGE: | 1″ (25 mm) |

| MAX FLOW RATE: |

Rubber = 56 gpm (212 lpm) |

| TPE = 56 gpm (212 lpm) | |

| PTFE – Full-Stroke = 49 gpm (185 lpm) | |

| PTFE – Reduced-Stroke = 44 gpm (168 lpm) | |

| MAX DIAMETER SOLIDS: | 1/4″ (6.4 mm) |

| MAX SUCTION LIFT CAPABILITY: |

Rubber = DRY – 17.6′ (5.4m) | WET – 30.6′ (9.3m) |

| TPE = DRY – 13.6′ (4.1m) | WET – 30.6′ (9.3m) | |

| PTFE – Full-Stroke – DRY – 18.2′ (5.5m) | WET – 29.5′ (9.0m) | |

| PTFE – Reduced-Stroke – DRY – 11.4′ (3.5m) | WET – 30.6′ (9.3m) | |

| DISPLACEMENT PER STROKE (1 cycle = 2 strokes): |

Rubber = 0.08 gal (0.30 L) |

| TPE = 0.09 gal (0.34 L) | |

| PTFE – Full-Stroke = 0.08 gal (0.3 L) | |

| PTFE – Reduced-Stroke = 0.06 gal (0.23 L) |

Benefits and Features:

- NPT and BSP threaded inlet/discharge liquid connections for quick disconnect/connect

- Decades of Proven Performance

- Clamped Connections for Faster Maintenance

- Low Cost

- Simple Installation

- Ease of Operation & Maintenance

Wetted Housings |

Non-Wetted Housings |

||

| MATERIAL | SHIP WEIGHT | DESCRIPTION | MATERIAL |

| Aluminum | 24 lbs (32 kg) | Center Block | Polypropylene, Acetal, Conductive Polypropylene |

| Stainless Steel | 23 lbs (51 kg) | Air Valve | Polypropylene, Acetal, Conductive Polypropylene |

| Ductile Iron | 21 lbs (47 kg) | ||

Elastomer Options

| Material | Temperature Limits |

|---|---|

| Buna-N | 10°F to 180°F (-12°C to 82°C) |

| EPDM | -60°F to 280°F (-51°C to 138°C) |

| FKM | -40°F to 350°F (-40°C to 177°C) |

| Neoprene | 0°F to 200°F (-18°C to 93°C) |

| PTFE | 40°F to 220°F (4°C to 104°C)

40°F to 300°F (4°C to 149°C) – 13 mm (1/2″) and 25 mm (1″) models only |

| Polyurethane | 10°F to 150°F (-12°C to 66°C) |

| Saniflex™ | -20°F to 220°F (-29°C to 104°C) |

| Wil-Flex™ | -40°F to 225°F (-40°C to +107°C) |

Certifications

CE Mark (Conformité Européene – European Conformity)

Wilden Pump & Engineering LLC has met the criteria for placing the CE mark on our product line. On December 3, 1999, Wilden fully self-certified its product line by meeting all the regulations of the Machinery and PED (Pressure Equipment) Directives. Every pump manufactured by Wilden will now receive the CE mark. Each pump box will also include a Safety Supplement manual in the eleven official languages of the European Community. This CE mark certification is indicative of Wilden’s pledge to providing our distributor network with all the sales tools necessary to excel in a global economy.

ATEX (ATmosphere EXplosible)

It is only natural that the worldwide leading producer of air-operated, double-diaphragm pumps complies with the ATEX 100A directive for explosive atmospheres. The European community and their safety are of utmost importance to us. We take responsibility for not only our product, but also for the supporting documentation and compliance of necessary directives. Wilden is proud to introduce our metallic X pumps that comply with ATEX 94/9/EC Group I, category M2 and Group II, category 2 zones G & D. Our plastic X pumps comply with ATEX 94/9/EC Group II, category 2, zone G.