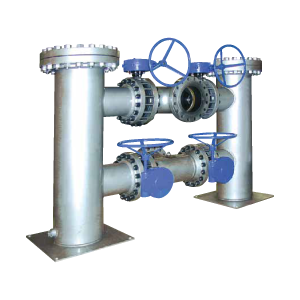

Model 950B BC – Bolted Cover Duplex Offset Strainer 2″ to 24″

Eaton Model 950B BC features two strainer basket housings with a valve flow diverter assembly connecting them. A duplex type basket strainer can operate continuously and the pipeline never has to be shut down. The Bolted Cover (BC) is designed for applications with infrequent basket changing and is available with a davit assembly cover for larger strainers with heavy covers, this makes it possible for a one-person operation. For applications with more frequent changing a hinged, quick opening cover secured by swing bolts is available (QOC) This is adaptable for higher pressure applications. For medium size strainers, 14″ to 16,” a davit assembly bolted cover is available. This permits one operator to engage the hinge and open the cover.

Duplex Housing for Continuous Operation

The Eaton Model 950B BC fabricated duplex strainers operate continuously and feature two strainer basket housings connected by valves. When the basket in the first housing becomes full, switching the flow to the second is easy using the butterfly valve assembly. Remove, clean or replace the first basket for use again; the pipeline never shuts down.

Strainer Screens

Strainer screens are stainless steel or other specified materials.

Backflush/Backwash Option

In systems with heavy, well defined solids and sediment, this option backflushes the system without shutting it the system down. A piping connection with an on/off backflush valve is fabricated at the strainer bottom and has a connection to the bottom of the strainer basket. When solids accumulate in the bottom of the basket, the backflush valve opens and the differential between the operating pressure and the backflush system removes the solids. The second step, backwashing, reverses the flow and removes residual dirt.

Optional Steam Jacketing

Available in carbon steel or stainless steel rated for service up to 450 °F (232 °C). This is ideal for the high temperatures required to process and transport heavy, viscous fluids without affecting the function or normal maintenance of the strainer. Steam jacketing maintains critical fluid temperature throughout the strainer.

Eaton customizes the strainers to meet special application requirements. Design and fabrication to “AD 2000-Merkblätter”, DIN EN 13445 or ASME Code and ANSI B31.1 are available.