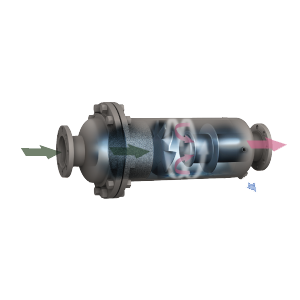

Eaton CLC Coalescer Separators are a two-stage vessel designed for separation of liquid in the form of a fine mist or fog from a gas or vapor. It’s primarily used in processes involving cooling or condensation, flashing or evaporation applications.

EATON CLC Coalescers Separators Features

- Two-stage design removes up to 99% of entrained liquid or solid particles larger than 4 microns as compared to one-stage coalescers capable of removing up to 10 microns

- Compact design

- Easy maintenance – the only maintenance required is the inspection, cleaning, or replacement of the demisting pad. This is easily accomplished through either a quick opening body closure or body flanges.

- Three flow configurations

- High Efficiency Over Wide Flow Range

Engineering Specifications

All gas/liquid separators are fabricated carbon steel or stainless steel construction with two-stage coalescer/separator design and flanged connections. Separators have an ASME Code Stamp.

EATON CLC Coalescers Separators Two-Stage Design

First stage: the coalescer stage, the smaller fluid droplets enter a special wire mesh demisting pad in the vessel. The purpose of this pad is to increase the size of the droplets as they pass through it so that they can be removed. The larger liquid droplets exit the demisting pad and enter the second separation stage.

Second stage: the droplets are centrifugally thrown to the outside wall by Eaton’s unique CENPELLAR™ air flow element and flow to the bottom of the vessel for draining. The Vortex Containment Plate (VCP), exclusive to Eaton separators, prevents the droplets from being re-entrained after separation.

|

|

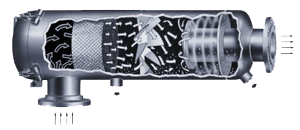

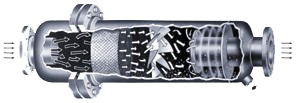

| EATON 36L CLC Separator with vertical up flow inlet and horizontal outlet | EATON 31L CLC Separator for horizontal or vertical downflow applications |

Eaton CLC Coalescer Separators High-Efficiency Separation Down to 4 Microns

The unique two-stage design of these Series CLC Coalescers/Separators allows them to remove 99% of all liquid and solid particles larger than 4 microns in size. Standard, one-stage separators are only capable of removing particles larger than 10 microns in size. The efficiency of Eaton’s Coalescer/Separator far exceeds that of any other type of centrifugal, cyclone, turbine or vane type separator. And it works with no moving parts to fail or wear out.

EATON CLC Coalescers Separators Applications

EATON CLC Coalescers Separators provide two-stage separation of liquid that is in the form of a fine mist or fog from a gas or vapor. The Coalescer/Separator is primarily used in applications where a fine mist is encountered in processes involving cooling, condensation, flashing, or evaporation, such as:

• Compressed refrigeration gases

• Evaporator overhead steam

• Compressed air prior to desiccant dryer beds

• High-pressure gas at injection wells

• Fuel gas lines to engines in power

• Industrial plants

• Natural gas and gas distribution lines

• Regulator stations